Business processes in today’s typical manufacturing environment is, at

best, full of information gaps. Within the major enterprise level systems

such as ERP or PLM most processes are based or focused on departmental issues

which means the processes are not cross-functional.

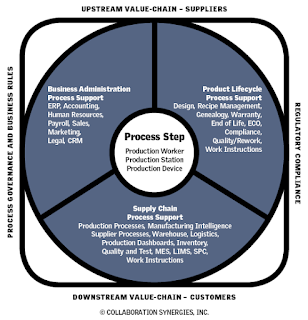

Production Process Management (PPM) is the missing link that supports

Smart Manufacturing. PPM is a specialized version of Business Process

Management (BPM) that describes the concept of applying process design and

management tools to the areas of manufacturing plant and supply chain

activities within and across the extended enterprise.

HOW MOST PROCESSES WORK TODAY

Business processes, especially those that connect to the plant floor,

operate based on the horizontal and sequential needs to produce products. But,

it has been difficult to include all necessary data management into one fully

integrated package.

One example is in a Human Resources application within ERP.

Employment history, wage administration, performance reviews, etc. are all

covered in fine detail. However, when the MES needs to confirm training

qualifications at a work station, the manual integration or “sneaker net” must

take over. The other option is to have the IT department build a significant,

custom application.

Another example is the retrieval of a pallet of material to be used at

the assembly line. There are different steps that can be taken to

complete this task, especially when working with small to global-sized

enterprises. The good news is that many of these steps are common.

Overall steps: Trigger—someone or some system (Kanban, production

schedule, replenishment alarm, etc.) recognizes the current work station

stockpile has reached the replenishment level and requests additional

supply.

Steps in a low volume environment:

|

Steps in a larger, higher velocity or

multiple SKU facility this may require a number of steps including:

|

The system could be as simple as

viewing a work station and noticing replenishment is necessary.

|

|

At this point the replenishment process example is not even half

developed and we can see the many information gaps and potential for

errors. The steps in this example will require multiple electronic

systems (ERP, MES, etc.) and manual steps to contribute to the process

execution and with each step there is greater potential for easy and costly

mistakes.

THE GOAL OF SMART MANUFACTURING

A key objective of Smart Manufacturing is addressing the need to

eliminate process gaps including manual steps like searching for information

across various electronic systems. This is a formidable task to say the

least.

The problem, as we all know, is the physical weaving of digital process

data through each of the electronic or manual processes across the extended

enterprise. The historical record of attempting to do this with systems

integration software coding techniques has caused much more grief than

satisfaction. So, other than

wishing for a better world, how can Smart Manufacturing be different?

●

Standards—There

is significant effort being made to develop and promote standard methods,

interfaces and technologies to exchange information between software applications.

●

Standards—There

is significant effort being made to develop and promote standard methods,

interfaces and technologies to exchange information between software applications.

●

New

applications—new applications are being developed that address specific

operations niches such as inventory movement or energy management or

environmental management concerns.

●

Process management—a

rapidly growing vendor market segment is providing new tools to assist in

planning, modeling, inventorying and managing your business and production

processes.

●

Process

execution—the past few years have seen substantial growth in the use of workflow

and business process management software systems. These approaches will

greatly enhance information management techniques on the plant floor.

WORKFLOW AND PROCESS MANAGEMENT

The newer concepts of Workflow and Process Management focus on

supporting the business process rather than on the features and functions of

siloed applications. A workflow consists of an orchestrated and

repeatable pattern of business activity enabled by the systematic organization

of resources into processes that transform materials, provide services, or

process information. These methodologies retrieve and provide data

elements from their source as necessary to accomplish work.

One example is the retrieval and display of work instructions to an

assembly station. This action may require information from many sources

but the key perspectives here are the delivery to the workstation, focus on the

business process, and focus on what is necessary to support each step in that

process. Workflow information management techniques were originally developed

in the nineties and have enjoyed extensive application success in a wide

variety of business applications including the plant floor.

HOW PPM HELPS SMART

MANUFACTURING

Business Process

Management is an approach that is based on workflow ideas but has a

substantially broader toolset. BPM has enjoyed extensive success since

the mid 2000s particularly in high volume processes found in administrative

industries such as insurance and finance.

As mentioned at

the start of this article, Production Process Management (PPM) is a specialized

version of BPM describing the concept of applying process design and management

tools to the areas of manufacturing plant and supply chain activities within

and across the extended enterprise.

Processes are

designed to follow chronological steps of how you want to run the business by

connecting and supporting predefined, sequenced events with the correct

information in a role-based form for the intended user. A process may be fully

electronic, fully or partially manual, or a hybrid of the two. One key

requirement is that the process is specific to, and configurable to fit, the

given business requirement and provides an easy path for revision and

improvement.

The Smart

Manufacturing Leadership Coalition (SMLC) and other sources support this

process-centric approach to information management and have provided some

examples of what might be possible.

1. Separate data from the application and invert the

historical manufacturing paradigm by bringing the data to the application

instead of the application to the data.

2. Provide actionable data, trust and visibility across

the supply/value chain.

3. Manage orchestration of standardized decision workflows

based on structured adaption and autonomy.

4. Deploy applications that can share data, data that can

share applications and applications that can connect to applications to achieve

horizontal enterprise views and actions.

5. Build applications that cross different time

constraints and seams, including the supply/value chain.

6. Provide applications that do not lose control of state.

7. An enterprise level platform to manage and support

applications/processes that can be company-wide standards yet specific to the

existing local plant information system infrastructure.

8. Build information tools that can differentiate company

performance and provide a competitive advantage through operational and

information management techniques.

9. Easy to understand applications/processes that can

evolve to solve changing business needs.

10. Information management concepts that allow operational

processes to be company owned intellectual property.

11.

An information management infrastructure that is easier

to manage, less costly and more supportive of users.

12. Computer driven processes that can be supported by

manual involvement, fully automatic or a combination of either.

The concept of using a process-centric approach to support production

is a key element of Smart Manufacturing. It creates a completely new

understanding of enterprise-wide information management -- an area fraught with

high IT cost, wide information gaps and much buyer angst.

The concept of using a process-centric approach to support production

is a key element of Smart Manufacturing. It creates a completely new

understanding of enterprise-wide information management -- an area fraught with

high IT cost, wide information gaps and much buyer angst.

The new process view gives manufacturers a wider horizon to think

strategically using information to build and maintain a competitive advantage

wholly based on how they want to run the business. The view is top down and

strategic. Response and global maneuverability are the issues, not data

collection or equipment efficiency. The executed process is the unit of

automation. How processes are defined and managed is the tactical stroke that

supports the enterprise strategy.

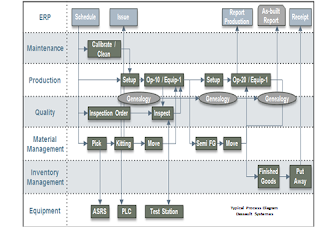

Manufacturing is best managed at the process level. Processes

span end-to-end across functions, departments, sites and capabilities, are

highly dynamic and must easily be updated to ensure manufacturing systems

remain agile to business changes.

For example, ERP started with End-to-End processes focused solely on

the fundamentals of the business. This must not only be extended across the

value chain in a horizontal dimension, but also taken deeper to drill down to

the specific details that support each step of production activity with

appropriate role based information.

The future perspective will be much less based on the functions within

an application, and much more on how information from any resource can best

support the user’s business and production processes. To paraphrase an

old political adage from a few years ago—“it’s all about the process.”

No comments:

Post a Comment