Antoine Snyman

INTRODUCTION

Even though the demand for the platinum

group metals (PGM) grew roughly 10 times over the last 40 years, the price

remained the stable. This forces

organisations to focus on asset management with specific attention to the

measurement of utilisation and performance of assets.

In the article titled Asset Performance Management: Proposing a Conceptual Model to Apply OEE

to a Continuous Process a conceptual model was presented. This article follows on that and the

objective of is to test the proposed model with actual results and prove the

validity thereof.

DATA

COLLECTION

Technology improved significantly since the

days of manual data capturing and data of this importance should leverage off

of the technology improvements (Muchiri and Pintelon, 2008; Ljungberg, 1998; Dal et

al., 2000; Kullh and Josefine, 2013; Jonsson and Lesshammar, 1999). Bearing this in mind, the first set of data

needed was an indication of whether the concentrator was running or not. A single, vital piece of equipment was

identified and used for this metric. If the

mill was both running and consuming a certain amount of electricity as

indicated by the plant historian, the plant was running.

When the plant was not running, a selection

screen was presented to the operator.

The operator could then select a downtime reason from a prepopulated

list and the times were allocated to a certain bucket, as presented in Figure 1. At the end of a time period, time buckets

were aggregated and availability was calculated:

Figure 1: OEE Time Allocation Model

For the same time period the Actual Mill

Feed Rate used in the Performance calculation was sourced from a SCADA system

and averaged over the amount of hours that the concentrator was actually

running. This provided the actual hourly

feed rate used in equation 2. The

Average of Top 6 Hourly Feed Rates was calculated from historical data and was

is seen as the nameplate performance of the concentrator as used in equation 2:

To calculate quality, the daily activities

of metallurgists were focussed on. Each

day metallurgists monitor and adjust certain metrics to ensure a high quality

output. If all of these values are in range, metallurgists are somewhat

convinced that the quality of the product will be high. Historical data was analysed and a range for

each metric was set up. A metric scored

100% when it operated in the specified range and deviances from the range

decreased the value thereof. Table 1 lists

the scores associated with the deviances.

Table

1: Deviance Penalties

Deviance from range

|

Score

|

Deviance from range

|

Score

|

0 %

|

100

%

|

51 –

60 %

|

40 %

|

1 –

10 %

|

90 %

|

61 –

70 %

|

30 %

|

11 –

20 %

|

80 %

|

71 –

80 %

|

20 %

|

21 –

30 %

|

70 %

|

81 –

90 %

|

10 %

|

31 –

40 %

|

60 %

|

90+

%

|

0 %

|

41 –

50 %

|

50 %

|

RESULTS

Data was collected over a time period north

of two years and it involved seven concentrators, but data for the first half

of 2014 were excluded from the results due to the notorious five month strike

in the industry during 2014. The collected data was then analysed, aggregated

and fed into the model presented.

It is important to note that the figures

used in this report are distorted figures due to the sake of

confidentiality. The concepts, however,

remains truthful.

Availability

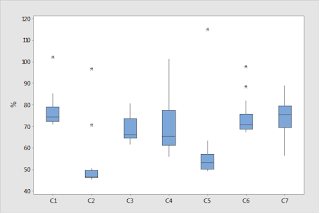

Figure 2: Boxplot of the availability metric

Figure 2 shows

boxplots for the availability metric and confirms the heterogeneity of

concentrators. Upon inspection C7’s wide

spread was attributed to erratic breakdown patterns and a process which was not

under control.

Performance

Similar to availability, the performance

metric the performance metric confirmed the heterogeneity of concentrators and suggested

that concentrators should perform between 80 and 90%.

It is noted that one of the concentrators occasionally

performed above 100%. Although this is possible,

it is not recommended as per asset management guidelines.

Quality

Figure 3: Boxplot of the quality metric

Again, the quality metric confirmed the

heterogeneity of concentrators and the indication is that the quality of the

product was largely dependent on the type of ore fed into the concentrator.

OEE

Not surprisingly, OEE indicated that each

concentrator operated within a narrow band but compared to other concentrators,

the spread is wider ranging between 45 and 80%. The trend in Figure 5

clearly shows a spike in data and upon inspection, it was learned that the

performance spiked when the concentrators started up post the five month long

strike.

Figure 4: Boxplot of OEE metric

Figure 5: OEE metric results

CONCULSION

The previous article highlighted the

importance of engineering asset management strategies and data integrity and

importance was highlighted earlier. As

per literature, data was collected electronically, classified by human

intervention and thereafter calculated and presented in the OEE model.

The model to measure asset performance was

tested in this article. A sensible

calculation for the availability metric was used where after a new performance metric

as offered was tested. Finally, a new

way of measuring quality in mining concentrators were tested. All three metrics held true and proved to be

useful in measuring the performance of assets.

The model proposed in the previous article

offers a bird’s eye view on the concentrators and reports on the overall

effectiveness and maintainability of assets.

It is proved that the model is valid and should be used by concentrator

management to operate more effectively.

REFERENCES

Dal, B., Tugwell, P. & Greatbanks, R.

2000. Overall equipment effectiveness as a measure of operational improvement-A

practical analysis. International Journal

of Operations & Production Management, 20(12), pp 1488-1502.

Jonsson,

P. & Lesshammar, M. 1999. Evaluation and improvement of manufacturing

performance measurement systems-the role of OEE. International Journal of Operations & Production Management,

19(1), pp 55-78.

Kullh,

A. & Josefine, A. 2013. Efficiency

and Productivity Improvements at a Platinum Concentrator. Masters of

Science in Mechanical Engineering, Chalmers University of Technology.

Ljungberg,

Õ. 1998. Measurement of overall equipment effectiveness as a basis for TPM

activities. International Journal of

Operations & Production Management, 18(5), pp 495-507.

Muchiri,

P. & Pintelon, L. 2008. Performance measurement using overall equipment

effectiveness (OEE): literature review and practical application discussion. International Journal of Production

Research, 46(13), pp 3517-3535.

AUTHOR

BIO:

Antoine obtained his bachelor’s degree in

industrial engineering from the University of Pretoria in 2006. Post studies, he started his career in

consulting where he quickly got awarded the responsibility and accountability

for the management and delivery of large projects for key clients. Currently, he is a specialist in his field

with responsibilities ranging across the entire value chain of the mining and

processing industry. He furthermore

completed his master’s degree in engineering, with focus on Engineering

Management in 2015 and is currently working at Lonmin Plc in Marikana, South

Africa.

No comments:

Post a Comment